Hey folks – especially those of you working in industrial automation or plant operations – I recently came across an interesting market report: Industrial Wireless Sensor Networks (IWSNs) are gaining serious momentum.

According to IMARC Group, the global IWSN market is projected to reach nearly $30 billion by 2033, more than triple its size today.

Now, I know what you’re thinking:

“Just another overhyped buzzword?”

“Can wireless really handle interference in a factory full of metal?”

“Is it worth investing in at all?”

And after reading several solid papers from NIST, SpringerLink, and IEEE, I realized: IWSNs aren’t just cool tech – they’re a real, practical piece of the smart factory puzzle.

So what exactly is an IWSN? And what does it do?

So what exactly is an IWSN? And what does it do?

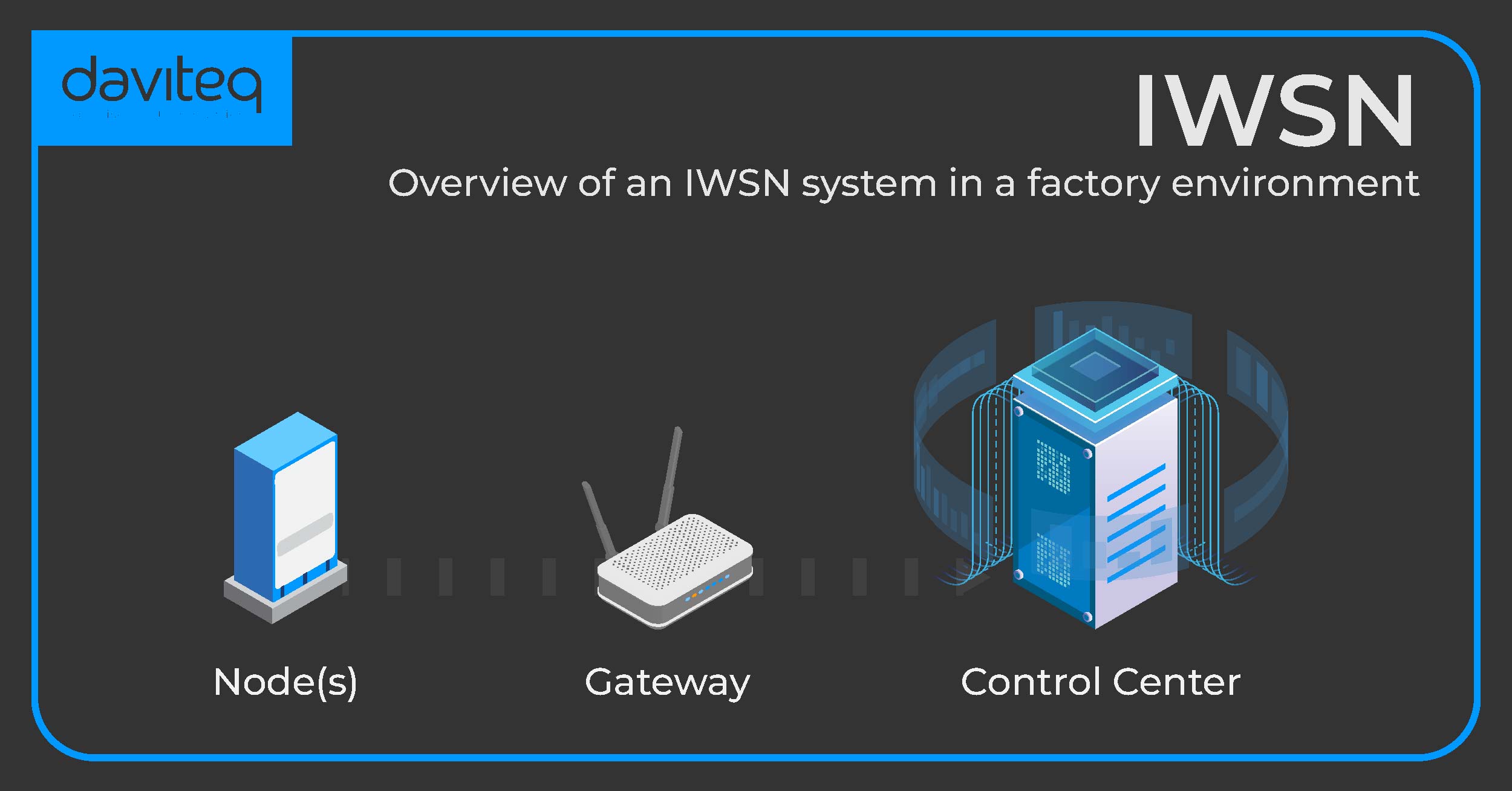

In plain terms: instead of wiring up sensors all over the plant and routing cables back to a central controller, you just install wireless sensors. These nodes automatically send data to a gateway, which then pushes the info to your PLC, SCADA, cloud platform, or dashboard – however you configure it.

Think of it like your home smart devices – a wireless temperature sensor or a Wi-Fi security cam. You just power it up, and it sends readings to your phone app.

Now multiply that by 100 (and crank up the technical reliability), and you’ve got an industrial-grade version for factories.

You can monitor things like:

- Motor vibration

- Room or equipment temperature

- Pressure inside pipes

- Energy consumption, and more

All in real-time, with zero trenching or cable routing.

So what’s the big deal? Why should factories care?

So what’s the big deal? Why should factories care?

-

Fast deployment:

If your layout changes often, or your lines are modular, wired sensors just get in the way. Wireless wins here. -

Predictive maintenance:

Use vibration/temperature data to spot failures before machines break down. Extend equipment life. -

Save costs:

A NIST study confirms wireless networks can cut installation costs and make sensor expansion way easier.

But don’t expect it to “just work” out of the box

But don’t expect it to “just work” out of the box

Here are 3 things you’ll need to plan for:

-

RF Interference

Factories full of metal = tough RF environment. You’ll need a solid mesh protocol, maybe even site-level RF surveys before deployment. -

Sensor power

Some nodes run for 3–5 years on battery. Others last longer, or you can use energy-harvesting sensors (from vibration, heat, etc.). Depends on your budget and use case. -

Security

It’s a wireless network – encrypt your data, authenticate your devices. This isn’t something to cut corners on.

Looking for a deeper dive?

Looking for a deeper dive?

If you’re curious about:

- Real-world deployments (like Iggesund paper mill in Sweden)

- Use in remote, high-risk environments (like oilfields in Nigeria)

- Academic insights on wireless protocols and energy harvesting tech

![]() Check out this in-depth article we put together, complete with links to NIST, IEEE, Springer, and arXiv sources:

Check out this in-depth article we put together, complete with links to NIST, IEEE, Springer, and arXiv sources:

![]() https://www.iot.daviteq.com/post/industrial-wireless-sensor-networks

https://www.iot.daviteq.com/post/industrial-wireless-sensor-networks

Hope this was useful – and if you’ve worked with IWSNs yourself, I’d love to hear your experience. Let’s share and learn from each other!